3D touch probe, inozivikanwawo seyekusangana sensor, sechinhu chinosarudzika paVMM, inogona kuve yakashongedzerwa neVMM kuti iwane akawanda ekuyera modhi, iyo inopa sisitimu ine hupfumi hwekuyera kugona uye inokodzera mhando dzakasiyana dzekushandisa.

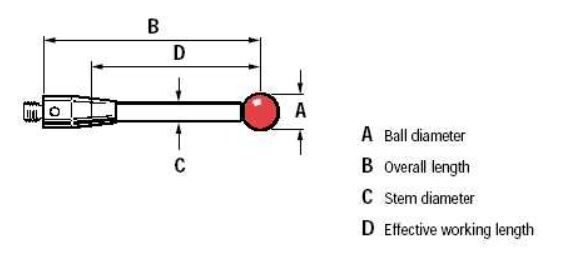

1. High precision trigger measurement: 3D touch probe inogona kuita high-precision trigger measure nekuita kuti probes pane zvakasiyana-siyana kuti uwane 3D coordinate points, nokudaro kuwana chiyero chepamusoro-chepamusoro.

2. Surface morphology kuyerwa: 3D touch probe inogona kubata-work-piece surface uye kuwana data, iyo inobatsira zvikuru kune yakaoma pamusoro morphology kuyerwa uye inogona kupa ruzivo rwakakwana rwejometri.

3. Chikamu chekutsvaga chekutsvaga: VMM yakashongedzerwa ne 3D touch probe inogona kushandiswa kuona zvikamu zvakadai sevhavha, protrusion, notch, nezvimwewo, uye kuyerwa kwakanyatsonaka kwezvinhu izvi zvinogona kuwanikwa kuburikidza ne trigger kuyerwa kweprobe.

4. Multi-point kuyerwa uye kuyera nzira kuronga: Iyo 3D touch probe inogona kuronga yega nzira dzemapoinzi akawanda ekuyerwa, nekudaro inowana kuyerwa kwe-multi-point uye kuvandudza zvakanyanya kuyerwa kwekuita.

5. Rutsigiro rweSoftware uye kugadzirisa data: Iyo 3D touch probe yakashongedzerwa nehunyanzvi yekuyera software, iyo inogona kugadzirisa, kuongorora, uye kuona data rakawanikwa, zvichiita kuti kuyerwa kwemhedzisiro kuve nyore kunzwisisa nekushandisa.

6.Kuyerwa kwemaitiro akaoma: Kune zvikamu zvine maitiro akaoma uye maumbirwo asina kukwana, 3D touch probe inogona kugadzirisa zviri nani uye kuyera, nokudaro kuwana ruzivo rwakakwana rwekuunganidza data.

Application

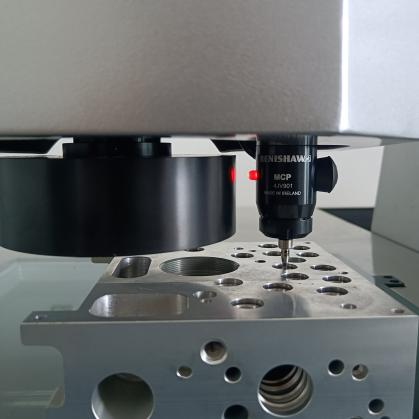

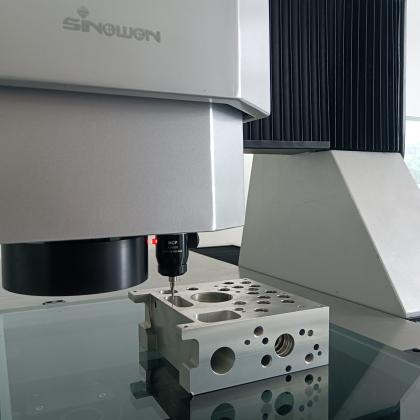

Kushongedza 3D yekubata probe paVMM inotsiva kusakwana kuyerwa kugona kweiyo optical lens kana yakatarisana nemasampuli ane akaomarara maficha uye zvimiro.Naizvozvo, mamiriro ekushandisa anopindirana neyechinyakare Coordinate Measuring Machine (CMM).

Chikwata chedu chinoratidza kuti VMM (ine 3D kubata probe) inogona kusarudzwa uye kukurudzirwa mumamiriro anotevera:

1. Kuyera kwechiyero hakuna kudarika kana kuenzana ne (5+L/200) um;

2. Masampuli anoda kuyerwa pazuva ari muhuwandu hukuru, saka kushandisa yechinyakare CMM kunodya nguva;

3. Iyo bhajeti haina kusangana nemari yeCMM, kana kuti hapana nzvimbo yakakwana yekuisa CMM.Tinogona kufunga kushandisa VMM pachinzvimbo.

Panyaya yeindasitiri yechigadzirwa, ndapota tarisa kune:

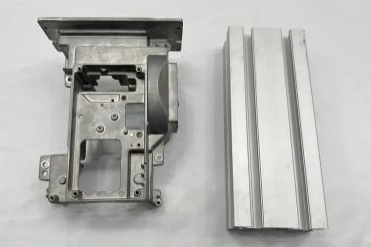

Mechanical parts, akadai semabhaudhi, nzungu, magiya, shafts;

Precision mold kugadzira, senge kutsika, kufa-casting zvikamu, optical molds, uye zvemagetsi packaging molds;

Aerospace, senge zvimiro zvemukati zvakagadzirwa nezvinhu zvinoumbwa;

Zvigadzirwa zvemagetsi, senge zvimwe zvikamu zvekurongedza;

Zvishandiso zvekurapa;Zvakadai semaimplants, zvigadziriso zvekurapa, uye stents.

Tikugashirei kuchiteshi chedu cheYouTube kuti uwane rumwe ruzivo nezve 3D kubata probe kuyerwa: https://www.youtube.com/watch?v=s27TOoD8HHM&list=PL1eUvesN07V9kJ5zZJUOuvUtzktCO06QK&index=4

Kana iwe uine chero zvinoenderana neprojekiti zvinodiwa, ndapota inzwa wakasununguka kutibata nesu kuti tibvunze.

Nguva yekutumira: Aug-31-2023