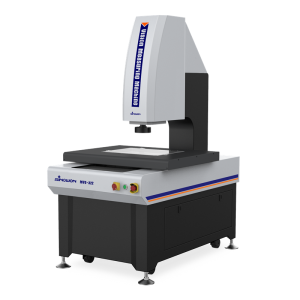

Machine Characteristic

● XYZ three-axis CNC automatic precision control, precise positioning;Indian Marble base and pillar, good stability;

● Precision linear guides, grinding-grade ball screws and AC servo motors, etc., ensure the accuracy and stability of the motion system;

● 0.5μm high-precision grating ruler to ensure the positioning accuracy and measurement accuracy of the system;

● High-resolution digital camera to meet the needs of clear observation and precise measurement;

● 8.3X high-definition optical lens, accurate zoom, one-time pixel correction;

● Program-controlled 5-ring 8-area LED surface illumination and parallel LED contour illumination system intelligently realize 256-level brightness adjustment;

● iMeasuring series automatic Vision measurement software, powerful and easy to operate.

Technical Specifications

|

Commodity |

2.5D Automatic Vision Measuring Machine |

3D Automatic Contact & Vision Measuring Machine |

2.5D Automatic Laser-Scan & Vision Measuring Machine |

3D Automatic Multisensory Measuring Machine |

||||||||||

|

Model |

MVS-322A |

MVS-322B |

MVS-322C |

MVS-322D |

||||||||||

|

Code# |

522-120G |

522-220G |

522-320G |

522-420G |

||||||||||

|

Sensor-Type |

A: One-Sensor Optical Zoom-lens Sensor |

B: Twin-Sensor Zoom-lens Sensor and Contact Probe Sensor |

C: Twin-Sensor Zoom-lens Sensor and Confocal Laser Sensor |

D: Tri-Sensor Zoom-lens Sensor Contact Probe Sensor Confocal Laser Sensor |

||||||||||

|

X/Y-axis Travel |

(300*200)mm |

|||||||||||||

|

Z-axis Travel |

200mm |

|||||||||||||

|

X/Y/Z-3 axis Linear Scale |

European Linear Scale Resolution: 0.5um |

|||||||||||||

|

Guidance Mode |

P-Class Precision linear guide, double-track double slider guide. |

|||||||||||||

|

Operation Mode |

Joystick controller, Mouse operation, automatic detection program. |

|||||||||||||

| Accuracy* |

XY-axis:≤2.2+L/200(um) |

|||||||||||||

|

Z-axis:≤5.0+L/200(um) |

||||||||||||||

|

Repeatability |

±2um |

|||||||||||||

|

Video System** |

1/2.9"/1.6Mpixel High Resolution Digital Camera |

|||||||||||||

|

8.3X Manual Electronic Feedback Lens |

||||||||||||||

|

Optical Magnification: 0.6X~5.0X; Video Magnification: 20X~170X (21.5” monitor) |

||||||||||||||

|

Field of View(mm) (D*H*V) |

Magnification |

0.6X |

1X |

1.5X |

2X |

2.5X |

3X |

3.5X |

4X |

4.5X |

5X |

|||

|

1/2.9"CCD |

10.35x8.28x6.21 |

6.21x4.97x3.73 |

4.14x3.31x2.48 |

3.11x2.48x1.86 |

2.48x1.99x1.49 |

2.07x1.66x1.24 |

1.77x1.42x1.06 |

1.55x1.24x0.93 |

1.38x1.10x0.83 |

1.24x0.99x0.75 |

||||

|

Illumination System |

Contour |

LED parallel contour illumination |

||||||||||||

|

Surface |

0~255 Stepless adjustable 5-ring 8-division LED surface illumination |

|||||||||||||

|

Measuring Software |

iMeasuring Software |

|||||||||||||

|

Load Capacity |

25Kg~50Kg |

|||||||||||||

|

Working Environment |

Temperature 20℃±2℃, temperature change<1℃/Hr; humidity 30%~80%RH; vibration<0.02g's, ≤15Hz. |

|||||||||||||

|

Power Supply |

220V/50Hz/10A |

|||||||||||||

|

Dimension (W*D*H) |

(1146mm*720mm*1664)mm |

|||||||||||||

|

Packing Size |

(1290*970*1920)mm |

|||||||||||||

|

Net Weight |

380Kg |

|||||||||||||

Note

● L is measured length(mm), the mechanical accuracy of Z-axis and focus accuracy is greatly related to the surface of the workpiece.

● **Magnification is approximate value, it is related to the dimension of monitor and resolution.

● Field of view(mm) = (diagonal*Horizontal*Vertical)

● 0.5X or 2X objective is optional available and realize image magnification: 13X~86X or 52X~344X.

Sinowon Vision Measuring Machine Dimension

|

Model |

Effective Measurement Travel mm |

Dimensions (L*W*H) mm |

|||

|

X-axis |

Y-axis |

Z-axis |

Machine dimensions |

Package dimensions |

|

|

MVS322 |

300mm |

200mm |

200mm |

(1146*720*1664)mm |

(1290*970*1920)mm |

|

MVS432 |

400mm |

300mm |

200mm |

(1331*840*1664)mm |

(1390*1060*1940)mm |

|

MVS542 |

500mm |

400mm |

200mm |

(1257*920*1640)mm |

(1450*1170*1900)mm |

Recommended computer configuration

The core of the Vision Measuring Machine is the control system and measurement software, and the computer system is the core carrier of all operations, requiring high stability and compatibility. Configure high-performance Dell computer Optiplex desktop and WIN 10/11 genuine authorized operating system to solve your worries.

| No. | Reference configuration | Qts |

| 1 | DELL Optiplex Desktop | 1 |

| 2 | G6405 Processor | 1 |

| 3 | 8G DDR4 2666 memory | 1 |

| 4 | M.2 2280 NVME 250G SSD | 1 |

| 5 | Intel UHD graphics card PCIE dual network port card | 1 |

| 6 | 21.5" monitors | 1 |

| 7 | Win10 64bit | 1 |

| 8 | 100-240V adaptive power supply | 1 |

| 9 | MS116 Mouse Set | 1 |

Configuration Model Description

|

Sensor Configuration |

2.5D |

3D |

Semiauto 2.5D |

Semiauto 3D |

|

Model |

MVS-322A |

MVS-322B |

MVS-322C |

MVS-322D |

|

Suffix |

A |

B |

C |

D |

|

Suffix Meaning |

Optics |

Optics + Probe |

Optics + Laser |

Optics + Probe + Laser |

|

Use Range |

Point • |

Point • |

Point • |

Point • |

|

Line — |

Line — |

Line — |

Line — |

|

|

Circle ○ |

Circle ○ |

Circle ○ |

Circle ○ |

|

|

Arc ⌒ |

Arc ⌒ |

Arc ⌒ |

Arc ⌒ |

|

|

Ellipse |

Ellipse |

Ellipse |

Ellipse |

|

|

Rectangle |

Rectangle |

Rectangle |

Rectangle |

|

|

Circular Groove |

Circular Groove |

Circular Groove |

Circular Groove |

|

|

Ring |

Ring |

Ring |

Ring |

|

|

Closed Curve |

Closed Curve |

Closed Curve |

Closed Curve |

|

|

Open Curve |

Open Curve |

Open Curve |

Open Curve |

|

|

High Magnification Height Measurement |

Probe height measurement |

Laser height measurement |

High-efficiency laser height measurement and stable probe height measurement |

|

|

------ |

Simple Regular 3D Dimensions |

------ |

Simple Regular 3D Dimensions |

|

|

Computable |

Distance |

Distance |

Distance |

Distance |

|

Angle ∠ |

Angle ∠ |

Angle ∠ |

Angle ∠ |

|

|

Diameter φ |

Diameter φ |

Diameter φ |

Diameter φ |

|

|

Radius ® |

Radius ® |

Radius ® |

Radius ® |

|

|

Roundness ○ |

Roundness ○ |

Roundness ○ |

Roundness ○ |

|

|

Straightness |

Straightness |

Straightness |

Straightness |

|

|

Parallelism |

Parallelism |

Parallelism |

Parallelism |

|

|

------ |

Perpendicularity |

------ |

Perpendicularity |

|

|

Concentricity |

Concentricity |

Concentricity |

Concentricity |

|

|

Angularity |

Angularity |

Angularity |

Angularity |

|

|

Symmetry |

Symmetry |

Symmetry |

Symmetry |

|

|

Flatness |

Flatness |

Flatness |

Flatness |

|

|

2D Position |

2D Position |

2D Position |

2D Position |

Note

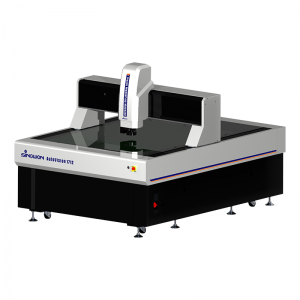

The X/Y/Z of the automatic Vision Measuring Machine are all controlled by high-precision servo motors. Only the first programming is done manually, and the subsequent operations and calculations are all done automatically by the machine, realizing high-efficiency batch measurement. This model is suitable for measuring complex products, various sizes, workpieces that need to be measured in large quantities, and high precision requirements for workpieces (this model is a gantry structure, which can improve the measurement accuracy and machine life compared with the traditional structure, and reduce subjective errors).