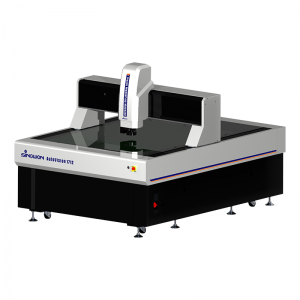

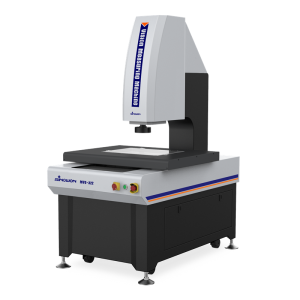

Karakteristik produk

● Moving Bridge jinis struktur, meja ukur tetep;l

● Four-sumbu CNC kanthi otomatis nutup daur ulang kontrol, pangukuran otomatis;l

● Indian Marble basa lan pilar, karo stabilitas apik sak ngukur;l

● Sinowon ngimpor skala linear RSF, resolusi 0.1um, mecah meneng werni lan AC servo motor etc. kanggo mesthekake tliti lan stabilitas saka sistem gerakan;

● Kamera warna HD sing diimpor kanggo nyukupi kabutuhan pengamatan sing jelas lan pangukuran sing akurat;

● 8.3x resolusi dhuwur motorized coaxial zoom lensa, akurat tikel lan siji kaping koreksi piksel mung perlu;

● Kanthi lumahing programmable 5-ring 8-division LED Cold Illumination lan kontur LED katerangan podo lan dibangun ing imbuhan cahya cerdas, iku bisa kanthi otomatis ngontrol padhange ing 8-divisi;

● fungsi kuat lan gampang operasi iMeasuring Software kanggo nambah kontrol kualitas;l

● Opsional MCP Probe lan Laser Senser Modul.Mesin bisa disesuaikan miturut syarat pelanggan.

Spesifikasi Teknis Mesin

| komoditas | 2.5D otomatissesantiMesin Ukur | 3D otomatisKontak & VisiMesin Ukur | 2.5D otomatisLaser-Scan & VisionMesin Ukur | 3D otomatisMultisensoriMesin Ukur | ||||||||||

| Model | AutoVision542A | AutoVision542B | AutoVision542C | AutoVision542D | ||||||||||

| Kode# | 523-180J | 523-280J | 523-380J | 523-480J | ||||||||||

| Tipe Sensor | Tipe A: Siji-SensorOptikLensa zoomSensor | B: Kembar-SensorSensor lensa zoomlanKontak Probe Sensor | C: Kembar-SensorSensor lensa zoomlanSensor Laser Konfokal | D: Tri-SensorSensor lensa zoomKontak Probe SensorSensor Laser Konfokal | ||||||||||

| X/Y-sumbu Travel | (500 * 400) mm | |||||||||||||

| Z-axis Travel | 200 mm | |||||||||||||

| Skala Linear sumbu X/Y/Z-3 | Resolusi Skala Linear Eropa: 0.1um | |||||||||||||

| Mode Pandhuan | Pandhuan linier Presisi P-Kelas, pandhuan panggeser pindho trek pindho. | |||||||||||||

| Mode operasi | Kontroler Joystick, Operasi Mouse, program deteksi otomatis. | |||||||||||||

| Akurasi* | Sumbu XY: ≤1.8+L/200(um) | |||||||||||||

| Sumbu-Z: ≤4+L/200(um) | ||||||||||||||

| Repeatability | ± 2um | |||||||||||||

| Sistem Video** | 1/1.8" Kamera Warna Digital Dhuwur Definition | |||||||||||||

| 8.3X Lensa Zoom Bermotor | ||||||||||||||

| Optical Magnification: 0.6X ~ 5.0X;Pembesaran Video: 20X~170X (monitor 21.5") | ||||||||||||||

| Lapangan sakaTampilan (mm)(D*H*V) | Magnification | 0.6X | 1X | 1.5X | 2X | 2.5X | 3X | 3.5X | 4X | 4.5X | 5X | |||

| 1/1.8 "CCD | 14.72x11.78x8.83 | 8.83x7.07x5.30 | 5.89x4.71x3.53 | 4.42x3.53x2.65 | 3.53x2.83x2.12 | 2.94x2.36x1.77 | 2.52x2.02x1.51 | 2.21x1.77x1.33 | 1.96x1.57x1.18 | 1.77x1.41x1.06 | ||||

| IluminasiSistem | Kontur | Iluminasi kontur paralel LED | ||||||||||||

| lumahing | 0~255 Stepless luwes 5-ring 8-divisi LED katerangan lumahing | |||||||||||||

| Piranti Lunak Pengukuran | Piranti Lunak iMeasuring | |||||||||||||

| Kapasitas Muatan | 25Kg~50Kg | |||||||||||||

| Lingkungan Kerja | Suhu 20 ℃ ± 2 ℃, owah-owahan suhu <1 ℃ / Jam;asor 30% ~ 80% RH;geter <0,02g kang, ≤15Hz. | |||||||||||||

| Power Supply | 220V / 50Hz / 10A | |||||||||||||

| Ukuran (W * D * H) | (1463*940*1591) mm | |||||||||||||

| Packing Ukuran | (1690 * 1300 * 2000) mm | |||||||||||||

| Bobot resik | 780 Kg | |||||||||||||

Cathetan

● L diukur dawa (mm), akurasi mechanical sumbu-Z lan akurasi fokus banget related kanggo lumahing workpiece.

● ** Magnification minangka nilai kira-kira, ana hubungane karo ukuran monitor lan resolusi.

● Bidang pandang(mm) = (diagonal*Horizontal*Vertikal)

0.5X utawa 2X objektif kasedhiya opsional lan éling perbesaran gambar: 10X~64.5X utawa 40X~258X.

Sinowon Vision Measuring Machine Dimension

| Model | Pangukuran Efektif Travel mm | Ukuran (L * W * H) mm | |||

| sumbu X | sumbu Y | sumbu Z | Dimensi mesin | Ukuran paket | |

| AutoVision432 | 300 mm | 400 mm | 200 mm | (1195*832*1579) mm | (1380 * 1170 * 1650) mm |

| AutoVision542 | 400 mm | 500 mm | 200 mm | (1463*940*1591) mm | (1690 * 1300 * 2000) mm |

| AutoVision652 | 500 mm | 600 mm | 200 mm | (1568 * 1040 * 1591) mm | (1800 * 1400 * 2000) mm |

| AutoVision862 | 600 mm | 800 mm | 200 mm | (1818*1157*1590) mm | (2300 * 1700 * 2000) mm |

| AutoVision1082 | 800 mm | 1000 mm | 200 mm | (2018 * 1357 * 1790) mm | (2500 * 1900 * 2200) mm |

Moving Bridge Vision Measuring Machine Model:

| Konfigurasi Sensor | 2.5D | 3D | Semi otomatis 2.5D | Semi otomatis 3D |

| Model | AutoVision542A | AutoVision542B | AutoVision542C | AutoVision542D |

| Sufiks | A | B | C | D |

| Arti Sufiks | Optik | Optik + Probe | Optik + Laser | Optik + Probe + Laser |

| Gunakake Range | Titik • | Titik • | Titik • | Titik • |

| garis - | garis - | garis - | garis - | |

| Lingkaran ○ | Lingkaran ○ | Lingkaran ○ | Lingkaran ○ | |

| Arc ⌒ | Arc ⌒ | Arc ⌒ | Arc ⌒ | |

| Ellipse | Ellipse | Ellipse | Ellipse | |

| Persegi panjang | Persegi panjang | Persegi panjang | Persegi panjang | |

| Alur bunder | Alur bunder | Alur bunder | Alur bunder | |

| dering | dering | dering | dering | |

| Curve Tertutup | Curve Tertutup | Curve Tertutup | Curve Tertutup | |

| Open Curve | Open Curve | Open Curve | Open Curve | |

| Pangukuran Dhuwur Magnifikasi Dhuwur | Pengukuran dhuwur probe | Pengukuran dhuwur laser | Pangukuran dhuwur laser efisiensi dhuwur lan pangukuran dhuwur probe stabil | |

| ------ | Ukuran 3D Biasa sing prasaja | ------ | Ukuran 3D Biasa sing prasaja | |

| Bisa diitung | kadohan | kadohan | kadohan | kadohan |

| Sudut ∠ | Sudut ∠ | Sudut ∠ | Sudut ∠ | |

| Dhiameter φ | Dhiameter φ | Dhiameter φ | Dhiameter φ | |

| Radius ® | Radius ® | Radius ® | Radius ® | |

| Bunder ○ | Bunder ○ | Bunder ○ | Bunder ○ | |

| Straightness | Straightness | Straightness | Straightness | |

| Paralelisme | Paralelisme | Paralelisme | Paralelisme | |

| ------ | Perpendicularity | ------ | Perpendicularity | |

| Konsentris | Konsentris | Konsentris | Konsentris | |

| Angularitas | Angularitas | Angularitas | Angularitas | |

| simetri | simetri | simetri | simetri | |

| Flatness | Flatness | Flatness | Flatness | |

| Posisi 2D | Posisi 2D | Posisi 2D | Posisi 2D |

Cathetan

X / Y / Z saka Mesin Pengukur Visi otomatis kabeh dikontrol dening motor servo kanthi presisi dhuwur.Mung program pisanan rampung kanthi manual, lan operasi lan petungan sakteruse kabeh rampung kanthi otomatis dening mesin, nyadari pangukuran batch efisiensi dhuwur.Model iki cocok kanggo ngukur produk rumit, macem-macem ukuran, workpieces sing kudu diukur ing jumlah gedhe, lan syarat tliti dhuwur kanggo workpieces (model iki struktur gantry, kang bisa nambah akurasi pangukuran lan umur mesin dibandhingake karo struktur tradisional. , lan nyuda kesalahan subyektif).