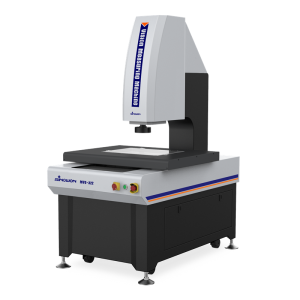

Projector Features

● The lifting system adopts linear guide rail and precision screw drive, which makes the lift drive more comfortable and stable;

● With precision toothless rod and fast movement locking device, ensure return error is within 2um;

● High accuracy A optical scale and precision working stage, ensure machine accuracy is within 3+L/200 um;

● HD zoom lens and HD color digital camera, ensure clear image without distortion;

● With programmable surface 4-ring 8-division LED cold light and contour LED parallel illumination, it can control the brightness of the 4-ring 8-division independently;

● With powerful iMeasuring software system , to enhance the control quality;

● Optional imported contact probes and 3D measuring software, it can help upgrade the machine to be coordinate measuring machine;

● Optional FexQMS measurement data analysis and real-time monitor software, enhance process control, reduce material consumption.

Projector Specification

|

Commodity |

Horizontal Video Projector |

|

Model |

PH-3015 |

|

Code# |

#542-310 |

|

Working Stage Travel |

355X125mm |

|

X/Y-axis Travel |

200X120mm |

|

Z axis |

110mm |

|

Measurement Accuracy* |

≤3+L/200um |

|

Resolution |

0.0005mm |

|

CCD |

1/2.9” 1.6MPiexl Digital CMOS Color Camera |

|

Zoom Lens** |

HD 6.5X Detented Zoom Lens |

|

Optical Magnification:0.7X-4.5X; Video Magnification:23X~158X |

|

|

Illuminating System (Software Control) |

Surface: Adjustable 4-ring 8-division 0~255-grade LED Cold Illumination |

|

Contour: LED Parallel illumination |

|

|

Working Environment |

Temp:20℃±2℃,Temp Variation<2℃/hr, Humidity:30%-80%RH,Vibration<0.002g,< 15HZ |

|

Measurement Software |

iMeasuring |

|

System |

Support XP, WIN7, WIN8,WIN10 32/64 Bit |

|

Power |

AC110V/60Hz; 220V/50Hz,600W |

|

Dimension |

1120X720X1100mm |

|

Weight |

165Kg |

Software Introduction

iMeasuring vision measurement software is a digital measurement software for geometric coordinate measurement based on Windows system. It supports image non-contact measurement, laser and confocal probe non-contact measurement and probe contact measurement. According to ISO, GPS, ASME geometric dimensions and tolerances Standard, digital measurement of linear and geometric dimensions such as shape, orientation, and position of part entities.

2. Geometric measurement:

n [2D Elements]: Point, Line, Circle, Arc, Curve, Keyway, Rectangle, Ellipse, Ring, Contour Scan.

Features: Lines, circles and arcs can be automatically identified and measured. For workpieces that need to find the highest point, extreme value measurement can be realized.

n [3D Elements]: Plane, Sphere, Cone, Cylinder, Groove.

Features: The operation interface is simple and easy to understand, covering common 3D elements. Realize the construction of points, lines, circles, arcs, ellipses, rectangles, grooves, rings, distances, angles, heights, open curves, closed curves, planes, cones, cylinders, and spheres.

3. Measurement Toolbar:

Realize point measurement, line measurement, circle measurement, arc measurement, ellipse measurement, rectangle measurement, groove measurement, ring measurement, curve measurement, contour measurement, height measurement, etc.

Profile Projector Standard Delivery

|

Commodity |

Code# |

Commodity |

Code# |

|

Digital Readout DP400 |

510-340 |

Mini Printer |

581-901 |

|

10X Objective Lens |

511-110 |

Power cable |

581-921 |

|

Anti-dust Cover |

511-911 |

Screen Clamp Device |

581-341 |

|

Warranty Card/ Certification |

/ |

Operation Manual/Packing List |

/ |

4. Construction toolbar

Guided by element type, it provides a variety of element construction functions such as translation, rotation, extraction, combination, parallel, vertical, mirroring, symmetry, intersection, and tangent.

Construct midpoints, intersections, lines, circles, arcs, ellipses, rectangles, grooves, O-rings, distances, angles, heights, open clouds, closed clouds, planes, calculation functions, and more.